The A(maze)ing Heist will be a hand-held, puzzle bank. A 6 inch by 6 inch cube will have one or more mazes, each on a face of the cube. The maze(s) must be solved in order to open the toy. 3-D Printing will be used to make the cube and the pieces.

|

| Figure One: Face |

Each face of the cube will be designed so that pieces will fit on it to create a maze. The cube will be made so that the sides are already connected to each other aside from the top part, so that it will open once the maze is completed. Each square inch of the faces will have four equally spaced pegs. The bottom of the pieces will be so that it will be able to fit over the pegs and stay snugly.

|

| Figure Two: Pieces, Top View (Left) and Side View (Right) |

The pieces are 1 inch by 1 inch cubes. The depth and width of the grooves in the cube will be large enough to fit a ball bearing, as shown in figure two. The tops of the grooves will be covered by a transparent material so that the ball bearing is seen, yet still encased. Each piece will have a differently shaped path, like a straight line or a t, to give variety for maze design. The ideal size of the ball bearing is still unknown. Many different sizes of the ball bearing will be tested to see which one fits the toy the best.

|

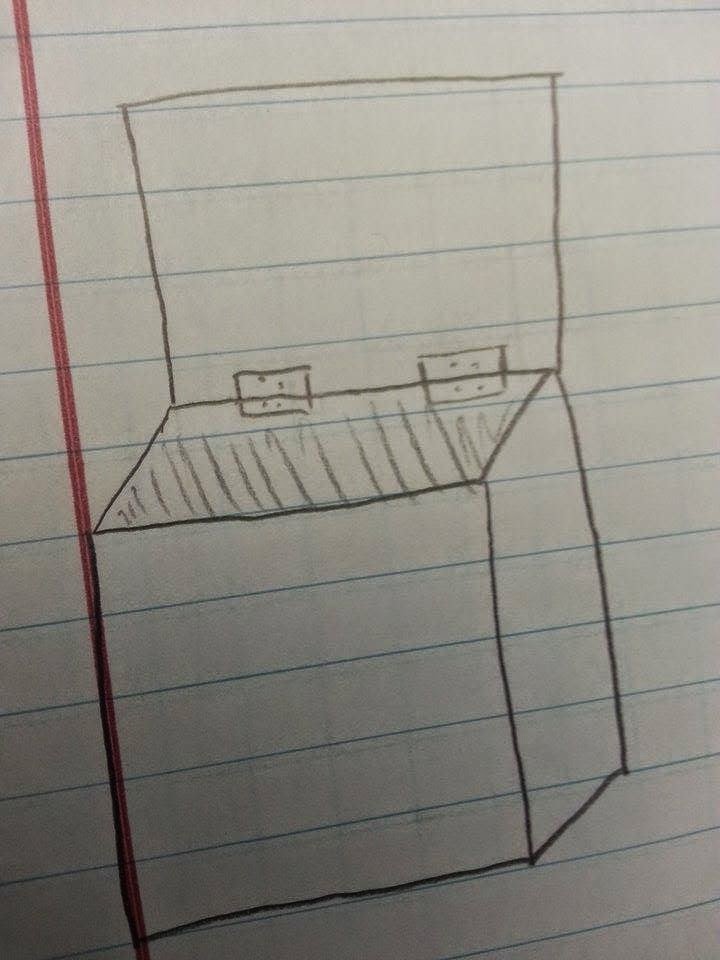

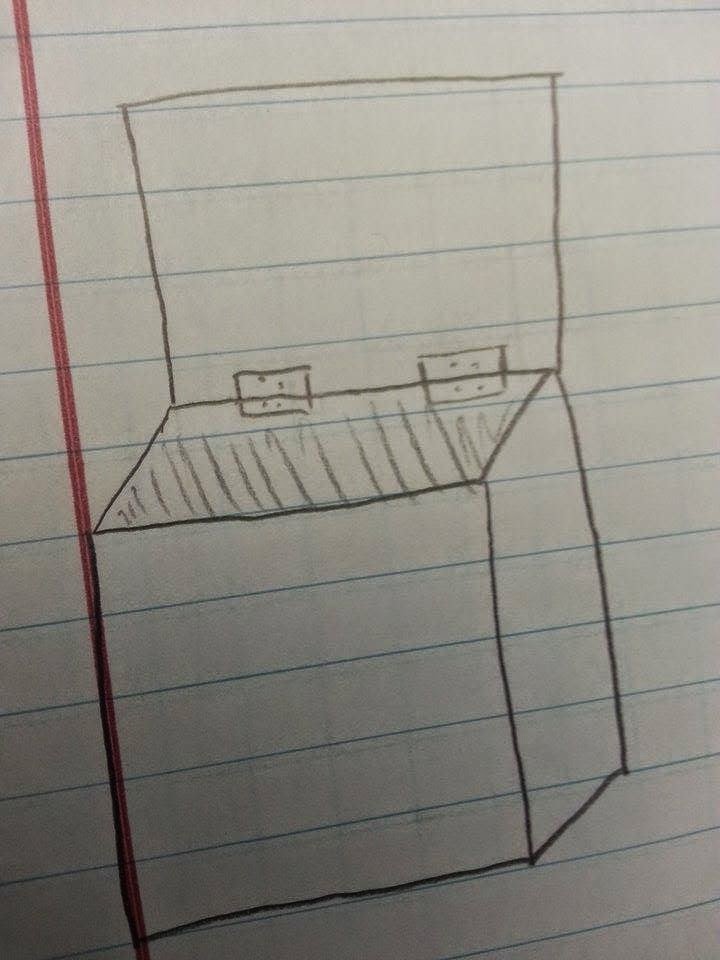

| Figure Three: Chest |

Once the final maze is solved, the ball will trigger and unlock the box, then top of the cube will pop out, almost like a treasure chest, as shown in figure three. Lock ideas are being brainstormed.

There are a few flaws with the design of the toy. First of all, a 6 inch by 6 inch cube is not too easily hand held. The mechanical design should be scaled to make something that would fit better. Also, the pieces of the maze should be made so that they would not be easy to take apart once the maze is put together to ensure the security of the maze.